The complete guide to flexible conduit system: how they are made, what tests they undergo, and how they are classified

8 Feb , 2023

How is a flexible conduit made? What are the tests it must undergo to ensure tightness and strength? How is a flexible conduit system built? This article is a mini-guide to flexible conduit system, where you can find all the information you need to learn about them.

Browse the dedicated section to discover all the electrical cable conduit available in our catalog.

Flexible conduit system: all the details

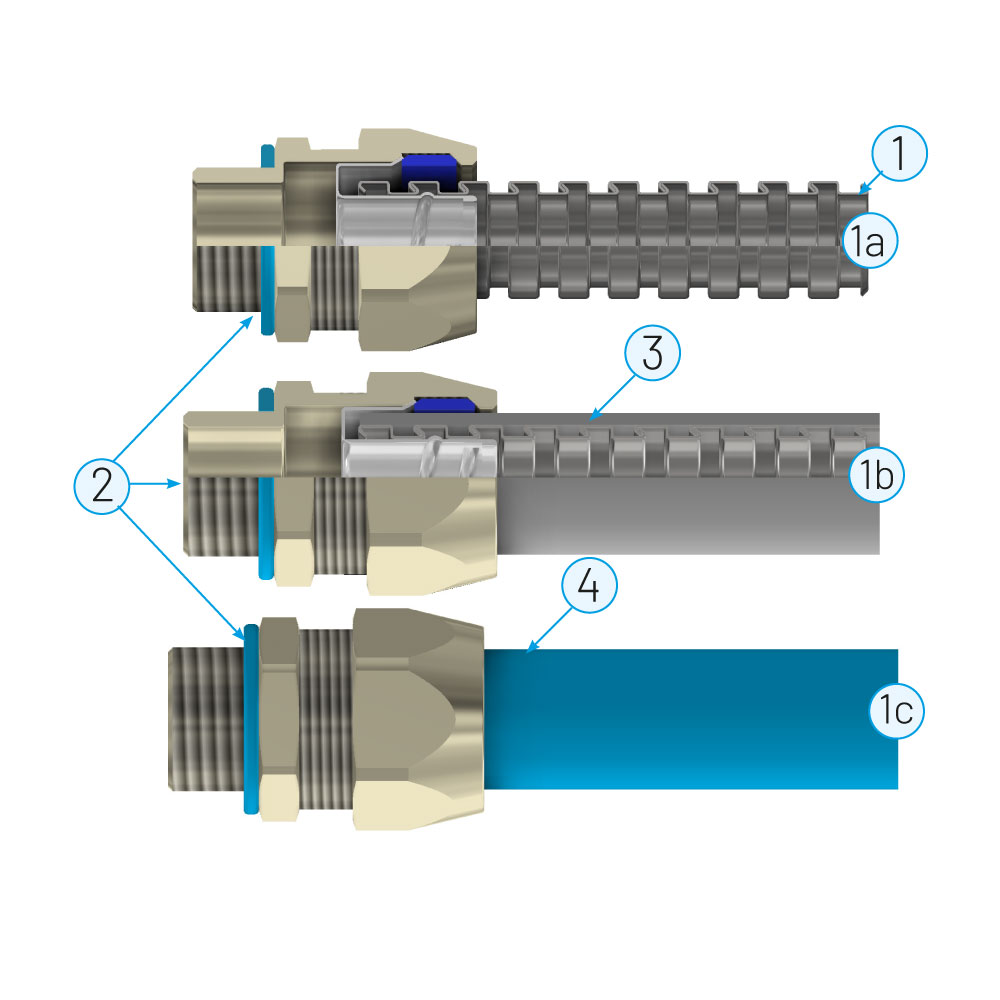

Let’s start with a conduit system, and let’s review it with the help of an explanatory figure.

What is it? It is a closed wiring system consisting of fittings for protecting and managing cables in electrical or communication systems, allowing them to be inserted and/or replaced but not to be inserted laterally.

Conduit (1): a part of a closed wiring system with a circular cross-section for cables in electrical or communication installations, allowing their insertion and/or replacement.

Conduit fitting (2): a device designed to join or end one or more components of a conduit system or to change its direction

Composite conduit (3) and/or conduit fitting (1): Pipe conduit or fitting including both metallic and non-metallic materials

Non-metallic conduit (plastic pipe) (4) and/or pipe fitting (plastic fitting): pipe or conduit fitting consisting only of a non-metallic material and without metallic components.

Flexible conduit (1,3): a conduit that can be bent by hand with reasonably light effort and intended to be bent throughout its lifespan

Reference standards: EN IEC 61386-1, IEC 61386-1

Basic construction of a flexible metal conduit system

The profile of a flexible conduit is formed by a spiral shape passing through the axis with equal space through a reinforced template. Flexible conduits are manufactured in galvanized steel, AISI 304 or AISI 316L stainless steel, bronze, and other materials.

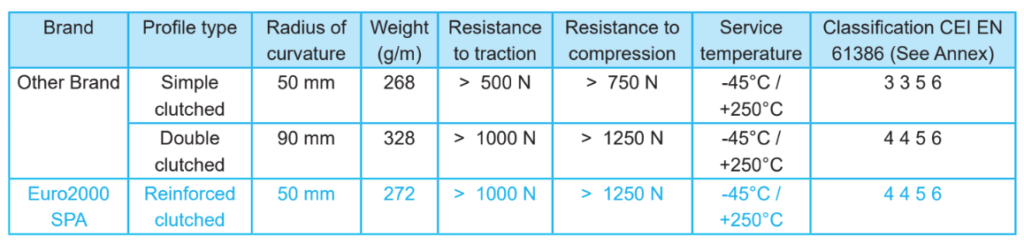

This table summarizes the typical characteristics of flexible conduit compared with the specific features of our flexible conduit.

Tests for flexible conduit according to EN IEC 61386 standards

There are several tests to assess the quality of a flexible conduit and its features. In particular, it is necessary to determine:

- Mechanical properties: different types of tests are used (for example tensile, compression, impact, bending, tests, and more) to determine the mechanical features of the material by applying an external force.

- Electrical properties: current or voltage is applied to test the basic elements such as electrical continuity, bonding test, electrical insulation strength, and resistance.

- External influences: tests are carried out for protection against water and dust. Due to water, ferrous metals become corrosive when exposed to weather agents, and thus a corrosion test is required as well. Learn more about the IP rating protection against weather agents or dust and water.

Quality control on Euro 2000 flexible conduit

At Euro 2000, our quality control department carries routine in-house testing for flexible conduit according to EN IEC 61386.

Compression testing for Euro 2000 flexible conduit

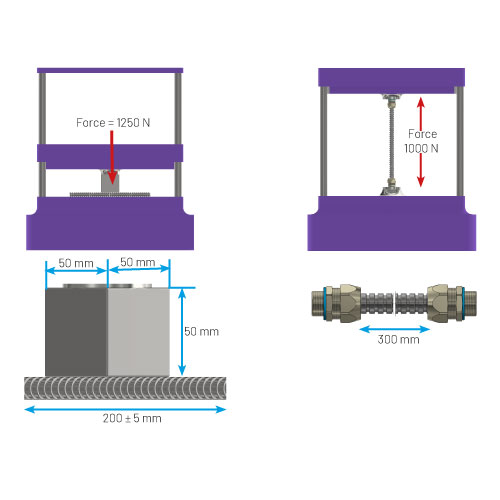

The test samples are positioned on a flat steel support, and an intermediate steel piece, as shown in Figure 3, is placed at the center of the sample. A continuously increasing compressive force is applied to the intermediate piece, reaching the values shown in Table 1 within 30 seconds. After the force (according to the classification) has been applied for (60 ± 2) seconds, the outer diameter of the sample is measured where flattening occurred without removing the force. The difference between the initial outer diameter and the diameter of the flattened sample must not exceed 25% of the initial outer diameter measured before the test.

The force and the intermediate piece are then removed, and 60 seconds after removal, the outer diameter of the sample is measured again where flattened. The difference between the initial diameter and the diameter of the flattened sample must not exceed 10% of the outer diameter as measured before the test. After the test, the specimens must not show visible cracks without further magnification.

Tensile test for Euro 2000 flexible conduit

A pipe sample and two end fittings are assembled according to the manufacturer’s instructions so that the total length (L) is about 300 mm.

The assembly is subjected to continuous and increasing tensile force for 30 to 40 seconds up to the value specified in Table 1. After 2 min ± 10 s the force is removed. If elongation occurs, the manufacturer shall provide instructions to assist in a safe installation. For conduit systems where the tensile strength is not stated, the tensile strength of the joint must meet the requirements of the applicable tests. After testing, the end fittings must remain properly assembled to the pipe, and there must be no visible damage.

Download this report for more information on conduit classification coding, and do not hesitate to contact us for more information.